Ammonia Removal Technology | AmmEL™ | AmmEL-H2™

The N4O Approach to Ammonia Removal

- No Nitrate - Carcinogen

- No Nitrous Oxide – Greenhouse Gas

- No Reduced Water Quality

- No Bio-fouling

- Only environmentally-friendly Nitrogen Gas

AmmEL Treats Ammonia Contaminated Water

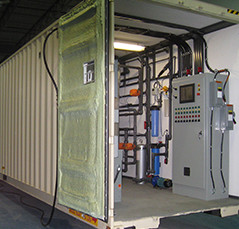

Current Water Technologies' patented AmmEL™ systems represent cost effective and environmentally sound treatment processes for the removal of dissolved ammonia from industrial and municipal water including wastewater, storm water, sewage effluent and mine waste water.

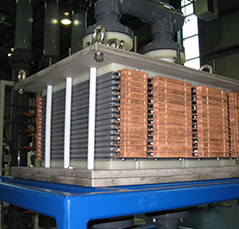

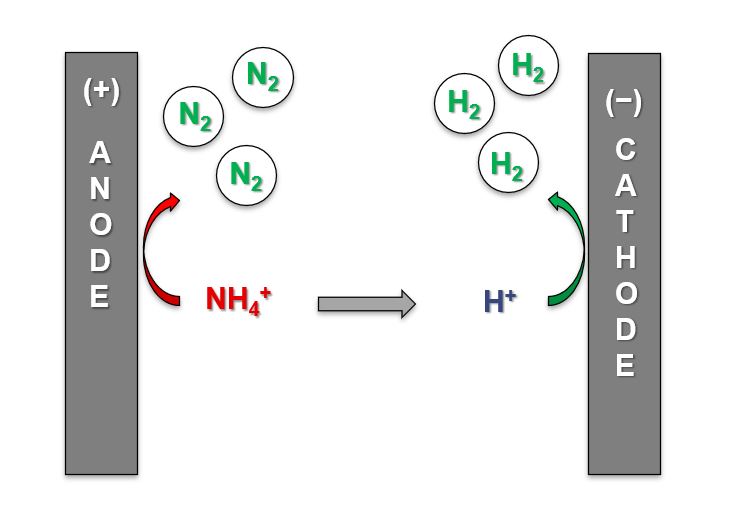

At the core of the AmmEL™ system is its proprietary self-cleaning electrochemical reactor that converts total ammonia directly to gaseous nitrogen without producing the carcinogen nitrate and the greenhouse gas nitrous oxide. Responsible management of ammonia will inhibit the proliferation of algae and improve water quality of receiving water bodies.

In contrast to conventional biological processes, the efficacy of Current Water Technologies' electrochemically based systems is not affected negatively by low temperature enabling responsible management of ammonia in northern regions of the globe year-round.

Some of the advantages of the AmmEL™ technology over conventional systems are:

- Treats very high concentrations of ammonium characteristic of bio-solids centrate/filtrate

- Capable of achieving very low concentrations of ammonium in the treated water (< 1 mg L-1)

- Does not produce the carcinogen nitrate

- Unlike biological treatment, the AmmEL™ system does not produce the greenhouse gas nitrous oxide

- Efficacy is independent of temperature

- Should qualify for greenhouse credits

- Treats water with high suspended solids and limited organic compounds

- Relatively small footprint

- Rapid start-up and shut-down

- Lower capital cost than bio-systems of similar capabilities

- Fully automated and remotely monitored, low maintenance

- No build-up or coating of microbiological slime within columns and therefore no reduction in ammonium adsorption efficiency

Green Hydrogen Production

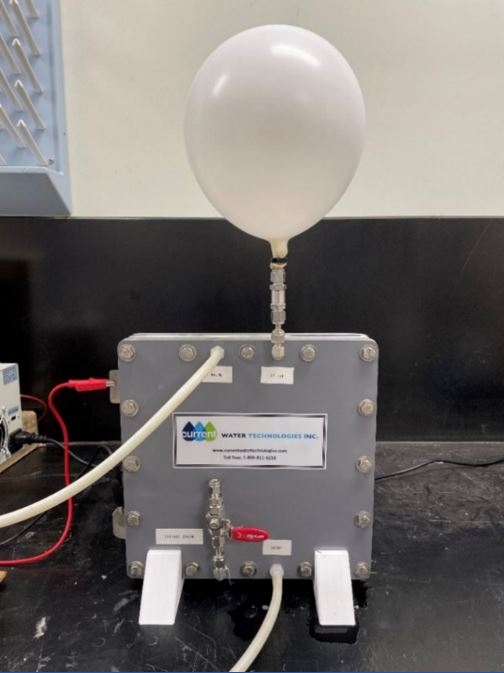

In addition to treating ammonia, the AmmEL-H2™ system produces a separate stream of high purity hydrogen gas from the electrolysis process.

AmmEL-LC (Lower Concentrations) (Tertiary Treatment)

Effective in reducing the ammonia concentrations from storm water, industrial and municipal wastewater systems.

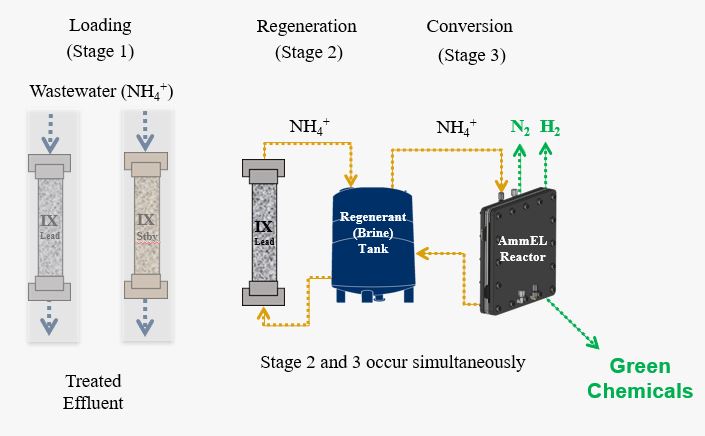

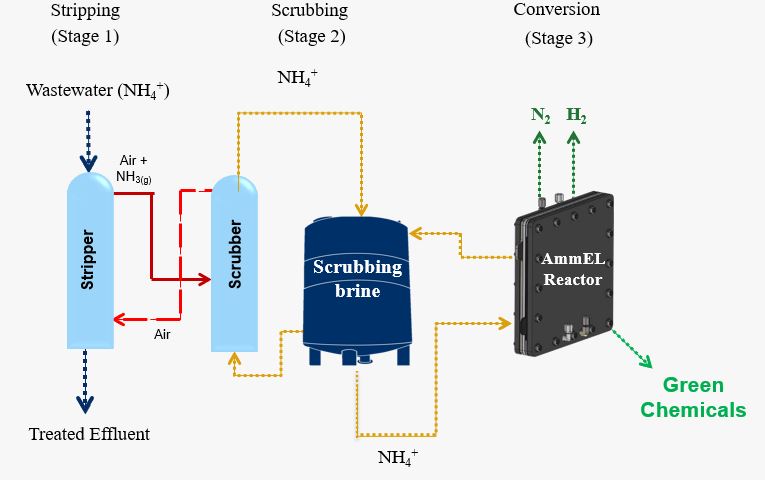

Current Water Technologies’ AmmEL-LC™ technology is proven effective at reducing inlet ammonium levels in the effluent water at municipal and industrial (i.e. mining, chemical and fertilizer industries, etc.) sites to below the effluent ammonium limits. Current Water Technologies' research team has developed, and proven the efficacy of, a natural ion exchange material capable of maintaining high ammonium removal rates while precluding the absorption of calcium, magnesium and strontium ions. The enhanced ion exchange material minimizes the adsorption of calcium, magnesium and strontium during the treatment of waste water while maintaining a high rate of ammonium removal.

AmmEL-HC (Higher Concentrations) (Treatment of ammonia in Centrate / Filtrate)

An advanced technology that is well suited for treatment of municipal and industrial wastewater, storm water as well as contaminated groundwater.

Municipal wastewater treatment plants can employ AmmEL-HC™ after sludge dewatering processes to prevent ammonia toxicity to the activated sludge process. It is an excellent complimentary system for treatment facilities during cool weather conditions when nutrient removal in biological reactors slows down. With a high removal rate immediately upon startup, it is able to divert excess loading from existing activated sludge processes during acclimation periods or system upsets.

Contact us to find out more about how one of CWTI’s novel AmmEL™ systems can help with your ammonia removal needs.